Metal screens are core elements of VAS scraper type self-cleaning filters, VFM and VSRF backwash filters and VSTF basket filters, and directly affect the filtration performance and final product quality. Metal baskets used as filter elements have stable filtration effects and long service life. Screens can be cleaned easily, reducing the costs and downtime of customers. More importantly, the filtration process is stable, and the quality of final products is improved.

Types of Metal Screens

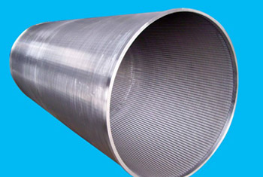

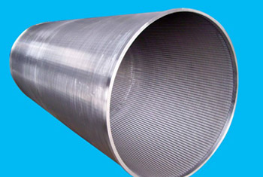

Metal Wedge Screens

VBN wedge screens (hereinafter referred to as VBN filter screens) are applicable to precision filtration and have the unique smooth filtering surface, good scraping and cleaning effects and uniform filter hole clearances. They are key elements for efficient and stable filtration. The integrated structure is solid and durable. Different from easy-to-wear ordinary woven screens, metal wedge screens can bear large positive and negative differential pressure and have long service life, and the hole diameter does not change along with pressure increase.

Technical Characteristics

■ Accuracy range: 30-2,000um

■ Surface gap accuracy: less than 5um deviation.

■ Body: 304 or 316L, with excellent corrosion resistance.

■ The gap is V-shaped to prevent jamming of impurities and keep the stable flow in a long time.

■ The outer and inner surfaces are smooth, materials can be easily scraped, and the scraper is worn little.

■ Metal wedge screens can be used for filtering thick impurities, such as sludge, soft agglomerate impurities, etc.

■ The surface is subject to special hardening and anti-wear treatment, greatly prolonging the service life.

■ The structure has high strength, and the gap is not deformed when the differential pressure increases.

■ Metal wedge screens can bear high-strength positive and negative pressure impact.

■ Thread width: 0.75mm, 1.0mm and 1.2mm.

Composite Metal Sintered Screens

Filtering surfaces of VBD composite metal sintered screens (hereinafter referred to as VBD composite screens) are the optimal combination of protective layer, filtering layer, diversion layer and reinforcing layer, which are integrated based on the advanced vacuum high-temperature combination technology.VBD composite screens have outstanding advantages of durability, washing resistance and good filtering effects.

Technical Characteristics

■ Accuracy range: 1-1,000um

■ The four layers are tightly integrated by means of combination.

■ The body is made of 316L and has excellent corrosion resistance.

■ Metal wires on the filtering layer have no deviation and good filtering effects can be achieved.

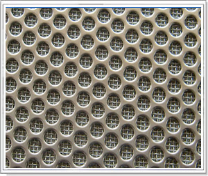

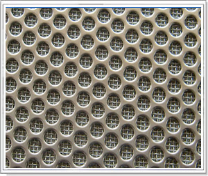

Perforated Screens

VBP perforated filter screens (hereinafter referred to as VBP perforated screens) are applicable to low-precision filtration. The minimum hole diameter is 500um, and large particles can be intercepted. The surface is formed by laser cutting and smoothed with accurate roundness. VBP perforated screens have good scraping and cleaning effects.

Exhibition